1

Expert Tribology Consulting

Leveraging a collective experience of over a century, our tribology experts are adept at resolving complex lubrication challenges in high-demand sectors such as Semiconductor, Aerospace, and Electron Microscopy. We specialize in creating tailored solutions that consider the nuances of deep vacuum, extreme temperatures, chemical exposure, material compatibility, and radiation exposure. We dispel uncertainty, empowering you to proceed confidently, knowing your lubrication strategy is optimized to prevent system failure and promote efficiency.

We appreciate that not every engineering team includes a lubrication specialist. That's why we're here, to fill that gap with our comprehensive knowledge and extensive experience. We seek to prevent both catastrophic failure due to inappropriate lubricant use, and unnecessary resource wastage by ensuring the full potential of each lubricant is realized. We're always a call away, your dedicated partner, here to navigate the complex world of tribology, ensuring your operations run smoothly.

2

Testing Capabilities

Microscopy and Imaging:

-

Microscopes-Compound and Stereo

-

Molecular Still

Spectroscopic and Chromatographic Analysis:

-

Fourier Transform Infrared (FT-IR) spectroscopy with Attenuated Total Reflectance (ATR) attachment

-

Gel Permeation Chromatography (GPC)

Thermal Analysis:

-

Pressure Differential Scanning Calorimeter (PDSC)

-

Thermogravimetric Analysis (TGA)

-

Aging Ovens

-

Dropping Point Apparatus

Tribology and Friction Testing:

-

Spiral Orbit Tribometer (SOT)

-

Four Ball Wear and Four Ball EP

Physical Properties Testing:

-

Penetrometer

-

Force Gauge

-

Density Determinations for Oil and Grease

-

Refractometer

-

Low & High Temperature Rheology (i.e., Brookfield Environmental Chamber)

-

Viscosity-low temperature, kinematic & absolute

Chemical Analysis:

-

pH Meter & Wet Chemistry Set Up

-

Elemental Analysis by ICP

Separation and Filtration Equipment:

-

Syringe & Large Cartridge Centrifuges

-

Ultrafiltration Equipment

Other Specialized Testing Equipment:

-

VOM volume resistivity of conductive greases

-

Foaming Tendency Apparatus

-

ASTM Evaporation Apparatus

-

Oil Separation Temperature and Pressure

-

Corrosion Testing

-

Soxhelt Apparatus

-

TA Rheometer

-

Water Washout & Water Spayoff

-

Microbalance

-

Clean Bench

-

Mechanical Workers

3

Custom Lubricant Solutions

TorrLube is a renowned pioneer in the development of high-performance lubricants, particularly specializing in extreme conditions such as deep vacuum and high temperatures. Our objective is to continually innovate, crafting lubricants that excel across an extensive temperature spectrum, ensure unparalleled thermo-oxidative stability in harsh environments, offer robust corrosion protection, and maintain superior film formation under boundary conditions.

Excitingly, TorrLube is soon to introduce a fresh range of lubricants crafted specifically for high-temperature, deep vacuum applications, along with a series of specialized lubricants for rolling element bearings, industrial gearboxes, sintered metal bearings, and automotive applications.

We formulate our oils and greases using a comprehensive array of commercially available synthetic fluids. This includes synthetic hydrocarbons, alkylated naphthalenes, diesters, polyolesters, polyglycols, CTFE’s, silicones, polyphenylethers, and perfluoropolyethers.

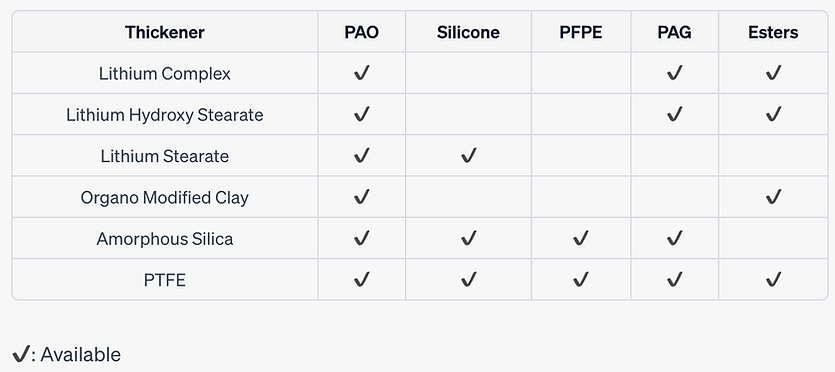

Below is a representative matrix showcasing the versatility of our grease production capabilities:

Our Versatile Range of Grease Formulations